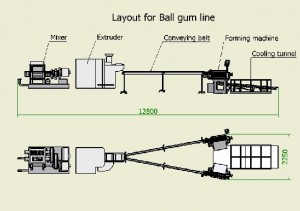

Gum ball machine,line

Complete plant for bubble gum balls

1.MIXER TYPE TY-MX-300UN

2. Extruder Type EX-100BG

3. Ball Forming Machine Type GF-FM – 35 GB

4. Cooling Tunnel Type GF-CT- 35 GB

OPTION:

Powdering unit:

Technical Description

This ball gum line is designed for the production of solid or hollow bubble gum balls with or without the fillings, with capacity of up to 300kg/h. (with two sets of forming machine and the hollow balls at 18 mms diameter)

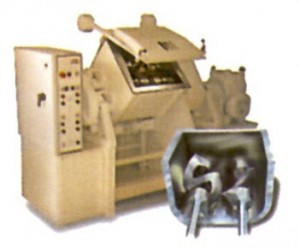

TY MIXER TYPE TW-MX-300UN

GF-MX-300 is a new design of machine based on the advances German technology. They are widely used in the fields of ball gum line,Bubble Gum line,Chewing gum line, Chemical and Pharmaceutical industries.

The main structures:

The trough and the mixing blades are made of stainless steel which is easy to be cleaned and offers a long service life.

The mixing blades of the mixer are of “z” shape, which can be used not only for mixing and kneading, but also for stirring, blending, beating, homogenizing and plastifying of the ingredients. The clearance between the wall and blades is very small to avoid the retain of the gum mass.

Take the advantage of the opposite rotation and inch-stop performance of the mixing blades, as well as the tilting function of the trough by means of the worm gear and screw driving system, makes the discharge of the ingredients very easy, safe, reliable and sanitary.

Double-jacket of the trough is provided for heating up the gum mass, and can be connected to its own heating system for warm water circulation.

The electric components and control system are of reliable and safe design with interconnection of various functions according the International standard.

Technical Data:

Volume: 300 L

Working capacity: 80-150 kg/batch

Tilting angle: QMAX=90°

Main motor: 22 kw

Motor for tilting system: 2.2kw

Motor for water pump: 0.5 kw

Water heating: 2×2 kw

Total power consumption: 23.75 kw

Blade Rotation speed: 19 rpm-28.5 rpm

Heating water temperature: ≤100℃ adjustable

Power supply: 3 phases, 380V, 50HZ

Machine weight: 3500 kg

Overall dimension: 2700X1600X1700mm

GF Extruder Type GF- EX-100 GB

Extruder type EX-100 GB is capable to offer 1-2 gum ropes with capacity of up to 300kg/hour for hollow or solid bubblegum balls with or without fillings. This machine is equipped with advanced electrical control system and mechanical conveying structure. It can feed one or two ball forming machines continuously and is reliable in safety and convenient for operation.

MECHANICAL CONSTRUCTION

The extruder is equipped with one barrel with two F 110 infeed rollers and two F 100 extrusion screws attached.

There’s a hopper on top of the barrel. Various forming dies are properly designed as requested, correspond to different shapes of product.

The extruder is equipped with two individual heating units. Heating or cooling of the barrels is controlled respectively by two water tanks via two thermo-regulators with digital display. Automatic adjustment starts when temperature has been set. The set temperature and the actual temperature are shown on the display.

The gearboxes are also installed on the extruder. Each unit includes gears gone through thermal procession. All axles are fixed on a ball bearing. The gears and the bearings run in an oil bath. The hydraulic reservoir is filled with special oil resistant to high-pressure. An electronic over-pressure protection device is fitted in each barrel accurately controlled by a microprocessor.

ELECTRIC APPLIANCES

One A.C. frequency converter together with main driving motors are introduced to infinitely adjust the extrusion speed.

Each set of extrusion screws is assigned with a variator to regulate the ratio depending on various raw materials to be extruded. “Speed Up or Down” Operation is achieved by a variator when the ratio has been fixed.

The extruder is equipped with two thermo-regulators with temperature display. All electric components and adjustment device are positioned at eye’s level. All contactors, relays and fuses are installed in the control cabinet.

TECHNICAL DATA:

|

Extrusion capacity:

|

Up to 300 kg/hour

|

|

Number of candy ropes:

|

1-2 rope(s)

|

|

Extrusion screw dia:

|

100 mm

|

|

Infeed roller dia:

|

110mm

|

|

Motor power:

|

2X5.5 kw

|

|

Power for water-heating:

|

2X6kw

|

|

Motor protection:

|

IP 55

|

|

Speed adjustment range:

|

1:35

|

|

Water consumption:

|

250lt/hour

|

|

Machine weight:

|

2300 kg

|

|

Overall dimension:

|

2350×1570×1550mm

|

Ball Forming Machine Type GF-FM- 35 GB

The rope coming from the extruder is taken over by the conveyor belt of the ball forming machine, powdered, equalized and cut to the length of the forming rollers. The rope pieces are pushed into the rollers, formed to the corresponding shape and then fed onto the cooling tunnel.

Product Range:

Minimum Diameter: 8 mm

Maximum Diameter: 30 mm

Mechanical Construction

The conveyor belt installed at the ball forming machine is running underneath the extrusion head and takes over the extruded rope. The conveyor belt is running intermittently.

The installed powder device is powdering the rope continuously, thus avoided the sticking. Two sets of equalizing rollers shape the rope to the final size. The sets of equalizing rollers are adjustable.

A rotating cutting knife is cutting the delivered rope into pieces corresponding to the length of the forming rollers. During the cutting, the conveyor belt is stopped.

A pusher transports the rope piece into the forming rollers. The front forming roller is mounted movably. As soon as the rope piece is pushed in, this roller is moving towards the other forming rollers and the rope pieces are shaped according to the profile of the rollers.

After the forming procedure the rolled products are pushed out. Another rope piece is pushed in and the forming procedure is continued.

The formed products are transported by a chute onto the cooling tunnel. The scrap edge products are collected in a bin.

Electrical Equipment

As drive unite a motor with 1.5 kw drive power and variable speed gear is built in. Speed adjustment in the range of 1:6. The electrical control and regulating instruments are clearly arranged in eye height. All contactors, relays and fuses are installed in the control cabinet.

Technical Data

Drive Power: 1.5kw

Length of forming rollers: 740mm

Diameter of the forming rollers: 50mm

Cooling Tunnel Type GF-CT- 35 GB

The rolled products coming from the ball forming machine are constantly kept in motion in the cooling tunnel and cooled down.

Mechanical Construction

Inside the cooling tunnel a plate is mounted keeping the products in motion. Underneath the plate a fan is installed which is constantly blowing air and thus is cooling down the products. This construction guarantees dimensionally stable products.

For being able to open the cooling tunnel, two flaps are provided on the upper side of the tunnel. At the discharge side supports for trays are fitted.

Electrical Equipment

All required switches, relays and fuses are installed in the control cabinet.

Technical Data

Fan: 0.16 kw

All capacity: 1600 cu.m./h

Vibrating motor: 0.33kw