Bubble gum line

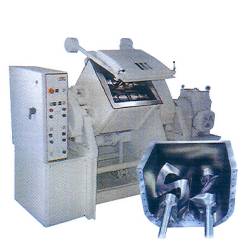

MIXER TYPE MX-300UN

MX-300UN is a new design of machine based on the advances German technology. They are widely used in the fields of Bubble Gum, Chewing Candy, Chemical and Pharmacal industries.

The main structures:

The trough and the mixing blades are made of stainless steel which are easy to clean and offers a long service life.

The mixing blades of the mixer are of “z” shape, which can be used not only for mixing and kneading, but also for stirring, blending, beating, homogenizing and plastifying of the ingredients. The clearance between the wall and blades is very small to avoid the retain of the gummass.

Take the advantage of the opposite rotation and inch-stop performance of the mixing blades, as well as the tilting function of the trough by means of the worm gear and screw driving system, makes the discharge of the ingredients very easy, safe, reliable and sanitary.

Double-jacket of the trough is provided for heating up the gummass, and can be connected to its own heating system for warm water circulation.

The electric components and control system are of reliable and safe design with interconnection of various functions according the International standard.

Technical Data:

Volume: 300 L

Working capacity: 80-180 kg/batch

Tilting angle: QMAX=90о

Main motor: 18.5 kw

Motor for tilting system: 0.75 kw

Motor for water pump: 0.5 kw

Water heating: 2×2 kw

Total power consumption:23.75 kw

Blade Rotation speed: 19 rpm-28.5 rpm

Heating water temperature: ≤100℃ adjustable

Power supply: to be specified by the customer

Machine weight: 3500 kg

Overall dimension: 2700X1600X1700mm

Bubble gum line,Bubble gum machine PART 2:

CO-EXTRUDER EX-100/2BG of Bubble gum machine

Co-extruder type EX-100/2BG is capable to offer 1-6 ropes of 1 color or 1-4 ropes of 2 colors with capacity of max.600kg/hour for bubblegum and chewy candy production. This machine is equipped with advanced electrical control system and mechanical convering structure. It can feed max. 6 sets cut & wrap machines continuously and is reliable in safety and convenient for operation.

MECHANICAL CONSTRUCTION

The extruder is equipped with two barrels mounted on one frame, each barrel with two F 110 infeed rollers and two F 100 extrusion screws attached.

Two sets of 60-liter hoppers on top of the barrels are built in two parts. Various forming dies are properly designed as requested, correspond to different shapes of product.

The extruder is equipped with three individual heating units. Heating or cooling of the barrels is controlled respectively by three water tanks via three thermo-regulators with digital display. Automatic adjustment starts when temperature has been set. The set temperature and the actual temperature are shown on the display.

The gearboxes are also installed on the extruder. Each unit includes gears gone through thermal procession. All axles are fixed on a ball bearing. The gears and the bearings run in an oil bath. The hydraulic reservoir is filled with special oil resistant to high-pressure. An electronic over-pressure protection device is fitted in each barrel accurately controlled by a microprocessor.

ELECTRIC APPLIANCES

Two A.C. frequency converters together with main driving motors are introduced to infinitely adjust the extrusion speed.

Each set of extrusion screws is assigned with a variator to regulate the ratio depending on various raw materials to be extruded. “Speed Up or Down” Operation is achieved by a variator when the ratio has been fixed.

The extruder is equipped with three thermo-regulators with temperature display. All electric components and adjustment device are positioned at eye’s level. All contactors, relays and fuses are installed in the control cabinet.

TECHNICAL DATA

|

Extrusion capacity: |

max.600 kg/hour |

|

Number of candy ropes: |

1-6 rope(s) |

|

Extrusion screw dia: |

100 mm |

|

Infeed roller dia: |

110mm |

|

Motor power: |

2X5.5 kw |

|

Power for water-heating: |

3X6kw |

|

Motor protection: |

IP 55 |

|

Speed adjustment range: |

1:35 |

|

Water consumption: |

300lt/hour |

|

Machine weight: |

2300 kg |

|

Overall dimension: |

2350×1570×1550mm |

Bubble gum line,Bubble gum machine PART 3: COOLING TUNNEL TYPE CT-9P/BG

WORKING PRINCIPLE

TW Cooling Tunnel of Bubble gum machine line is optimized by George Food Machinery Ltd based on the advanced European technology. Refrigeration units and circulation device are adopted to achieve constant temperature and humidity in the cooling tunnel, in which 1-4 candy/gum ropes is transported smoothly by nine conveyor belts.

MAIN CONSTRUCTION

Transportation

Nine conveyor belts of 6000mmX350mm are driven by a 2.2 kw motor with a double-stage chain system to take over the continuously extruded ropes. Special transferring device is located at the entrance and the exit to deliver the extruded ropes to the wrappers. Running speed of the conveyor belts is infinitely adjustable within the range of 0-0.5m/s (maximum 30m/minute) and is controlled by a Japanese frequency converter.

Support

Strong supports are provided along the tunnel. Insulation walls around the tunnel is surrounded by slabs of rolled sheet steel filled with foamed insulating stuffing. Two glass doors stands in the front and at the rear side for the supervision of interior running status. There are six doors altogether for checking and maintenance the tunnel.

Air Circulation

The air condenser in the tunnel is cooled by an exterior refrigeration unit. Two axle ventilators propel the cool air in the tunnel to circulate to reach the set temperature. Three adjustable electrical units for heating and dehydration are also installed to help the tunnel operation under constant humidity and temperature in accordance with technical requirement for specific product.

Electric Control

The complete set of electric components are fitted in the control cabinet located at the end of the cooling tunnel. A microprocessor made by the Omron Co., Japan is introduced to set and regulate transportation speed and temperature and to start and stop ventilators as well as electric heating device. A main operation panel is fitted at the infeed side and an auxiliary panel is located at the rear side of the tunnel. It is possible to check, set and adjust through the main panel the belt speed, and to start/stop ventilators and electric heating device and to turn off the tunnel. An emergency stop button is fitted on the auxiliary panel.

Refrigeration

A complete refrigeration system working with refrigerant R22 is composed of imported compressor, a refrigerating unit, a condencer and is characterized by appropriate working pressure. The system offers smooth running of the belt, low noise and excellent cooling effect. Four refrigerating units are de-frosted in intervals and can work continuously under low temperature.

Technical Data

Environment: temperature ≤25 0 C, relative humidity ≤55%

Cooling tunnel: temperature 4-140 C, relative humidity 50%

Power supply: to be specified by the customer

Cooling water intake pressure: ≥0.15 Mpa

Cooling water flux: 10 m3/H

Power consumption: 50 kva

Power of Refrigeration system: 15Hp

Cooling capacity: 20 kw

Water temperature: < 30℃

Overall dimension: 7400X1540X2000

Machine weight: 5500kg

Bubble gum line,Bubble gum machine PART 4 : WRAPPING MACHINE TYPE CW-600BZ

This wrapping machine is for the shaping, cutting and packaging of bubble gum and chewy candy with rectangular shape in side folding wrapping style. The machine can wrap products with 2 sheets of waxed paper, i.e. the inner and outer paper. Both paper can be fed from the 2 reels with the outer one printed. It can fulfil side-folding or back-folding operation depending on your choice.

Product Range

Length: 20-40mm

Width: 12-25mm

Height: 5-16mm

Specific Characteristic of the machine

Output: up to 600 wraps/min

Wrapping Speed Display

Fault Display and Automatic Switch-off Device

Sealing Temperature Display

Counter

Centering Device

“No gum, no paper” Device

2 paper-reels for the feeding of inner and outer waxed paper

The machine is ideally designed. Easy and fast assembling and disassembling of the components facilitate maintenance and cleaning. All electric and electronic parts are imported to guarantee optimum performance and safety.

Technical Data

Capacity: 5.6KW

Power supply: to be specified by the customer

Weight: 1250kg

Dimension: 1845×1185×1795mm

Wrapping material: Heatsealable paper, Aluminium foil or PE film

|